Athens Living Lab

5G to improve logistic processes automation in ports and mission critical services with continuous business & technical-related 5G system optimization.

Living Lab description

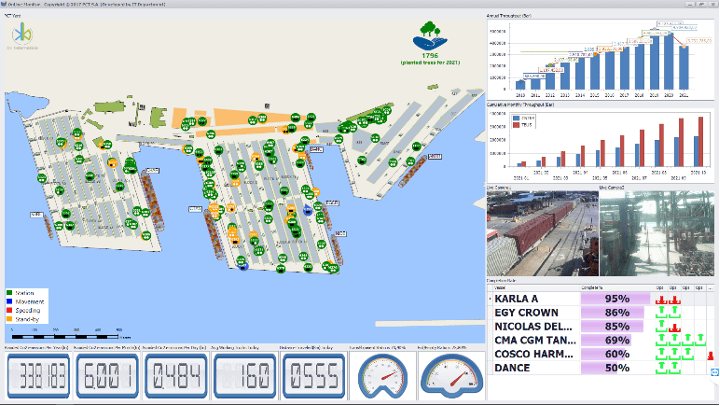

Piraeus Container Terminal (PCT) is a large dynamic company owned by COSCO, located at Piraeus, in Athens. PCT’s main activities are the provision of loading/unloading and storage services for import and export containers including cargoes which use Piraeus terminal only as an intermediary station of transport. The strategic location of Piraeus makes it an ideal hub for destinations in the Central/Eastern Mediterranean and the Black Sea. The continuous development of the port in both yard equipment and innovative technological solutions has raised it to rank 4 among the busiest European Ports of 2020, and is expected to rise even more. Three partners, PCT, ICCS and Vodafone will exploit 5G technology focusing in port operations within and outside the port premises, enabling real-time tracking and enhanced visibility of 5G yard trucks for service optimization, job allocation and predictive maintenance services, 5G enabled video analytics targeting safety/security and logistics applications orchestrated as NFV-MANO services to 5G-IoT nodes, and real-time monitoring of the logistics supply chain with live tracking of 5G connected (external) trucks in-bound at Piraeus port.

5G Innovation

The Athens LL develops a set of use cases and platforms that communicate over the private 5G NSA network with different types of end devices (5G-Trucks, 5G-Cranes, 5G-IoT, 5G UEs). 5G technology will enable the use case innovations exploiting eMBB (Enhanced Mobile Broadband) service and low latency transmissions of 5G, including NFV-MANO based applications and service orchestration, pioneering far edge computing solutions, computer vision and AI/ML video analytics.

The portfolio of application innovations includes live tracking of 5G (yard and external) truck operations for optimal container job allocation and predictive maintenance services by exploiting telemetry data (from various on-truck sensors) aggregated over the fleet of 5G connected trucks in (near-)real time; UHD transmissions of massive uplink video data from deployed 5G-IoT devices for port operations monitoring, security/safety applications aided by video analytics services; and automation for ports (i.e. port control, logistics and remote automation services with NFV-MANO support at the far-edge).

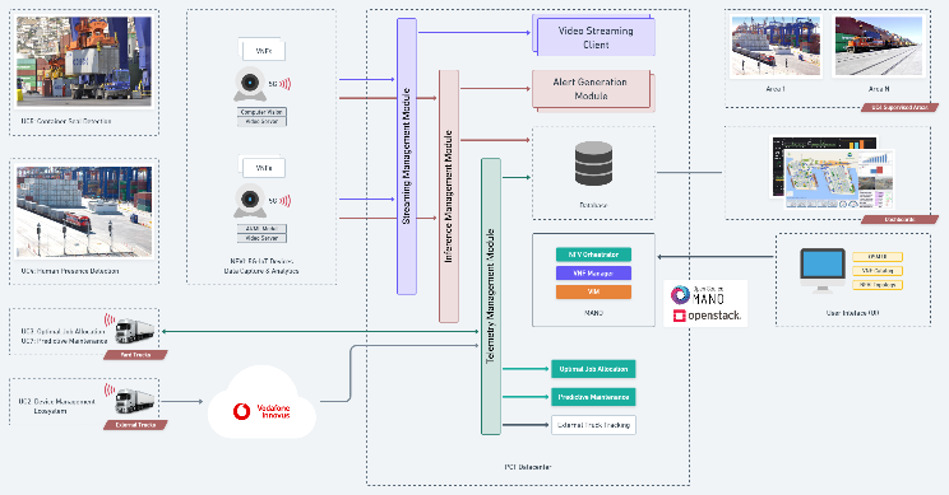

Figure 1: Living Lab Athens – 5G IoT System

Use Cases

5G External Truck in Port Operations (UC2: Device Management Platform Ecosystem)

At the port multiple trucks arrive and depart continuously. Each truck driver can be aware of another trucks position by using a mobile app that displays location of all trucks on the port. Traditionally trucks are fitted with GPS devices that transmit data over GPRS networks. A remote server is used to receive device’s GPS position. Each data transmit is based on the following simplified flow:

• Device CPU reads the GPS location.

• The device modem opens a connection.

• Location data are transmitted to the platform.

• Data are processed and pushed to mobile devices or another server for further

The above flow contains a time delay between the time of the actual location and the time is visualized to the user. This process includes the following time costs:

• Device signal acquisition.

• Data post from device to server.

• Data processing on the server.

• Data transferred from the server to the device.

This use case aims to leverage the 5G low latency in order to reduce the data transit time. On top of this, the device will be configured to run as a streaming device with no network negotiation times (open/close transmit sockets etc.). This setup lays the foundation for future enhancements, leveraging the 5G spectrum, such as live dash camera with video information from other trucks.

Figure 2: 5G External Truck Management Platform

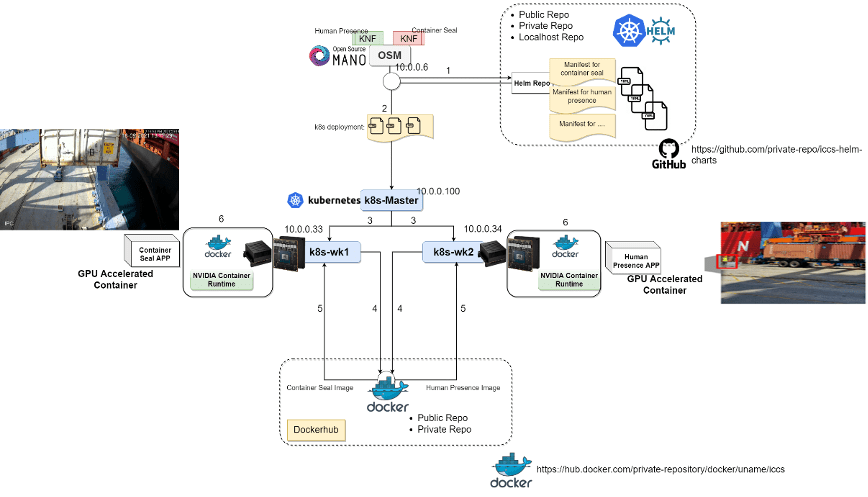

5G IoT System (Across Use Case)

A 5G-IoT system will be deployed in Athens LL supporting a set of use cases that utilize 5G-IoT devices, 5G Quayside Cranes (QC) and data from 5G (yard) truck sensors. The platform is based on open-source solutions for service orchestration and life cycle management of applications at the (far-)edge. Particularly, OpenSource MANO (OSM) will be equipped with a Kubernetes cluster to deploy container based network functions (CNFs), tailored to video analytics services in various 5G-IoT nodes distributed at the Port’s areas of interest.

The IoT nodes (and relevant analytics services) will exploit the eMBB service and low latency transmissions of 5G, to deliver voluminous (inferenced) video streams for safety/security applications and monitoring, as well as port control, logistics and remote automation targeting the efficiency of port operations.

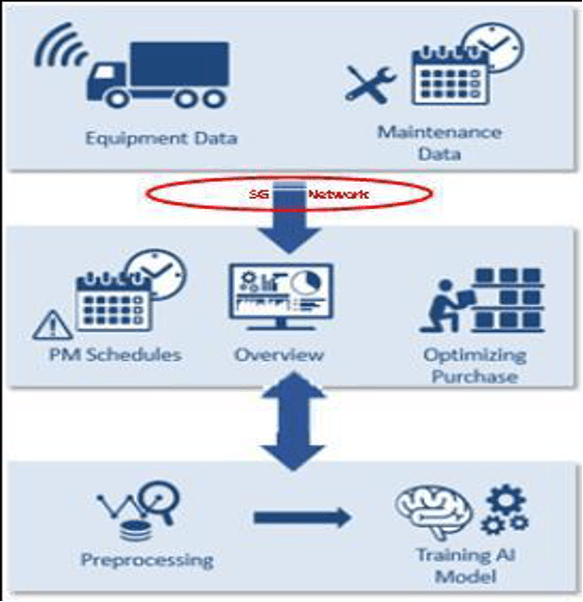

5G Yard Trucks in Port Operations (UC3: Optimal selection of yard trucks & UC7: Predictive Maintenance)

The port heavily relies on internal yard trucks for the horizontal movement of containers between stacking areas and loading/unloading areas for vessels and road/rail. This use case targets safety and the efficiency of truck operations (i.e., focusing on the mobility of trucks within the port terminal, container job assignment based on localization data, and predictive maintenance service).

| Type | Sensors/Devices | 5G Enabler |

| 5G Yard Truck | 4K Camera, CAN-Bus, GNSS, Container presence sensors, Tablet. | eMBB (enhanced Mobile Broadband), low latency |

Table 1: 5G Yard Truck and Sensors

Each truck is equipped with a telematics device, connected to the sensors of Table 1. The camera is installed on the yard truck to enhance the perception/view of a truck’s surrounding, e.g., targeting potential blind spots. UHD (uplink) video data streams are transmitted from the truck to a GPU enabled edge node at the port premises.

The node service (i.e., orchestrated CNF) will process the video data to detect human presence in close proximity of the truck for collision and accident avoidance. In case of such events detection, alerts are rapidly delivered to the truck (over the low latency 5G link) alerting the driver. Both central management platform and the driver (through the installed Tablet in the truck cabin) will be able to receive live the inferenced video stream (with the corresponding bounding boxes/annotation of the frames).

Additionally, live GNSS data (including truck’s moving direction, speed, etc.) from the fleet of 5G connected trucks are accumulated at the central (traffic) management platform, and exploited by the container job allocation algorithm for selecting (in real time) the optimal (i.e., closest) truck available for a job (e.g., unloading of a vessel). Accurate and real time localization data will reduce the travel distance of yard trucks, fuel consumption, vessel/job completion time as well as other dependent services at the Port of Piraeus.

Finally, direct access to CAN-Bus data from the live operation of yard trucks will be exploited by the predictive maintenance algorithm. The proposed tool will capture historical and recent status data for the assets in question, utilized by the ML algorithm and driving a per yard-vehicle data driven approach (schedule of purchases, storage of parts, proactive maintenance), by taking advantage of 5G technology that provides a flexible, reliable and predictable environment to remotely keep track of the connected assets on a real time basis

Figure 3: 5G Yard truck live tracking and predictive maintenance

5G Cranes and 5G-IoT in Port Operations (UC4: Optimal Surveillance Cameras and Video Analytics & UC5: Automation for Ports: Port Control, Logistics and Remote Automation)

| Type | Sensors/Devices | 5G Enabler |

| 5G IoT devices installed on quay side cranes and other fixed locations | 4K Camera(s) | eMBB (enhanced Mobile Broadband), low latency |

Table 2: 5G Crane and IoT in Port Operations

Use case 5 on the other hand is focused on port control, logistics and remote automation, and aims at detecting the presence/absence of container seals without intervention from human personnel. QCs are equipped with 4K camera(s) and GPU enabled 5G IoT nodes that employ computer vision techniques to infer the presence (absence) of seals at the loading/unloading process of vessels.

The overall monitoring of vessel operations is further enhanced by delivering live inferenced video streams of crane operations from the 5G node exploiting the eMBB service of the private 5G NSA network in Athens LL.

Figure 4: 5G and IoT (far-edge) Video Analytics with NFV-MANO Support